Choose Your Language

Request a Quote

Monprene® TPE

- Home

- Supplier Products

- Teknor Apex

- Monprene TPE

Thermoplastic Elastomers, or TPEs, are a premier choice of soft, flexible materials due to their robust properties, cost effectiveness, and design optionality. As a global leader in compounding, Teknor Apex offers one of the broadest portfolios of TPE technologies in the industry, including styrenic block copolymer (SBC) compounds, polyolefin blends (TPE-O or TPO), thermoplastic vulcanizates (TPE-Vs or TPVs), polyurethane compounds (TPE-U or TPU), and other specialty blends.

From soft-touch toothbrush grips to ergonomic power tool handles, consumers recognize the comfort and safety that Monprene® TPE provides. This diverse product line was born of market requirements and encompasses multiple TPE chemistries, including SBC, TPV, TPO, and TPU. Standard grades are available for quick sampling, and Monprene® can be customized to meet specific aesthetic or functional requirements, granting designers, OEMs, and processors superior flexibility when designing new products.

Taking a focused approach to address each market's needs, Teknor Apex has engineered each TPE product line to meet the requirements of the specific industry that it serves. Standard grades often meet the applicable regulations and specifications for that industry. As a result, Teknor Apex’s TPE compounds are likely to be pre-qualified for your application, which can accelerate your speed to market with new products. Characteristics and properties found across Monprene® product lines include:

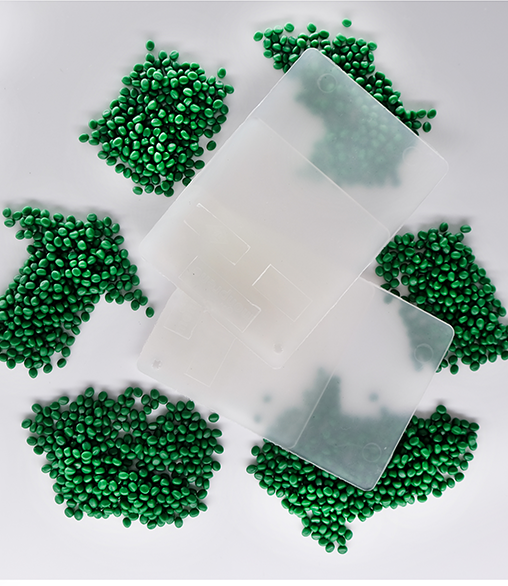

New eco-conscious Monprene® TPE in partnership with UBQ™ materials.

UBQ™ is a sustainable plastic substitute converted entirely from organic and unrecyclable waste.

Biobased and highly recyclable, UBQ™ offers a climate-positive solution towards a circular economy. By replacing oil-based raw materials with UBQ™ in TPE formulations, Teknor Apex is helping to address the global waste crisis, preserving finite natural resources, and reducing the carbon footprint of your end products.

Available in 70 Shore A and pre-colored black, the Monprene® S3 CP-15170 BLK grade performs and processes comparably to prime TPE. This is a high flow grade designed specifically for injection molding or overmolding onto polypropylene. This TPE is ideal for consumer products applications requiring flexibility, soft-touch components like anti-slip or comfort grip, and improved ergonomics. Common applications include hand and power tools, consumer electronics, and appliances.

With a climate-positive impact and cost-competitive price, UBQ™ empowers manufacturers with a simple transition to greater sustainability.

Features & Benefits

From food contact applications and housewares to personal electronics, pet products and white goods or appliances, you can differentiate your consumer products withMonprene®. Monprene® thermoplastic elastomers add cushioning, protection, or a soft-touch grip to everyday consumer products. Monprene® can be formulated to achieve various tactile qualities, such as a smooth, silky feel or a tacky surface for an enhanced grip. Often ideal for 2-shot or insert molding, Monprene® TPEs exhibit excellent adhesion to rigid plastic substrates for more comfortable handles, tighter seals, and anti-slip surfaces. Monprene® can be custom colored to match any palette seamlessly your product's unique brand. Typical applications include:

|

|

|

Creating innovative packaging that meets stringent performance requirements while also satisfying sustainability goals and maintaining cost effectiveness is simple when you have the right material for your application. From specialty TPE blends used in PE and PP closures in a hot-fill liner process, to high performance TPEs with superior oxygen and moisture barrier properties used in Aseptic-filled protein drink applications or ROPP aluminum closures, Teknor Apex TPEs can provide the solution. Common applications include:

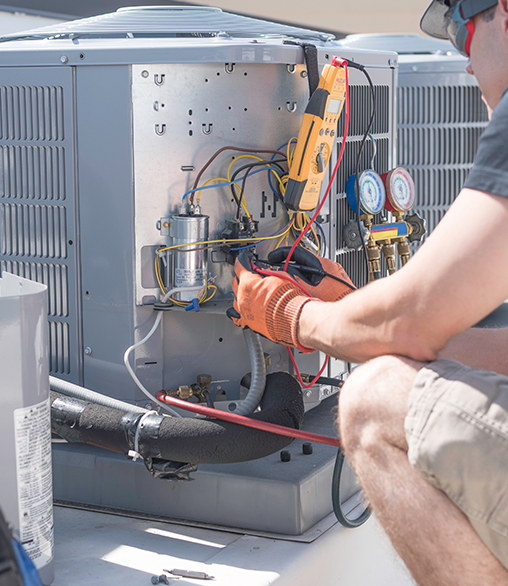

Monprene® TPEs are frequently chosen for specialized industrial applications due to their outstanding performance. Monprene® TPEs are very elastic and remain flexible even at sub-zero temperatures, making them a premier option for sealing applications in fluid management systems, from automatic sprinkler gaskets to HVAC seals. These versatile materials can be customized for different end use environments with a variety of properties like improved abrasion resistance or UV stability. Monprene® TPEs can be filled or unfilled depending on your cost and performance needs. Typical applications include:

|

TPS CP-23060 NAT MONPRENE |

||

|

TPS CP-24038 XRD1 MONPRENE |

TPS PR-12241 NAT MONPRENE |

|

|

TPS OM-11260 NAT XRD1 MONPRENE |

||

|

TPS CP-19034 NAT MONPRENE |