Excellent Dimensional Stability and High-Heat Tolerance

Ryton® PPS (polyphenylene sulfide) is a family of semi-crystalline polymers with excellent dimensional stability and a high-heat tolerance. This inherently flame retardant high-performance polymer exhibits outstanding chemical resistance compared to benchmark PEEK and fluoropolymers.

With a unique combination of properties and an optimal cost/performance balance, Ryton® PPS delivers a remarkable set of performance and processing benefits for various applications. Ryton® PPS is a highly efficient material of choice that offers tremendous chemical resistance, thermal performance, creep resistance and design flexibility.

Ryton® PPS (polyphenylene sulfide) compounds offer a unique combination of properties and a cost/performance balance unmatched by other engineering thermoplastics. Characteristics and properties found across Ryton® product lines include:

|

|

Ryton® PPS high-performance polymers are optimal for various appliance applications, thanks to their combination of processability and performance. Ryton® PPS helps appliance OEMs meet challenging market trends, while generating cost-saving opportunities when compared to conventional metals, thermosets or other engineering materials.

Typical applications include:

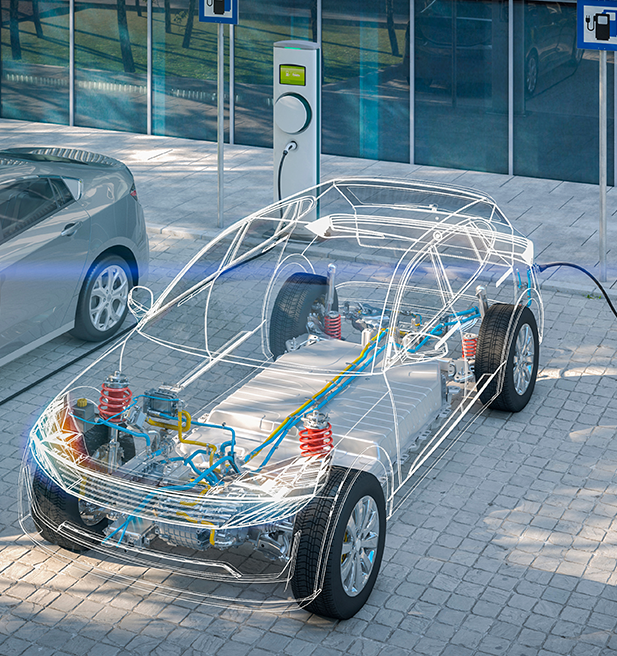

Ryton® PPS is the material of choice for a variety of automotive applications and components, due to its ability to withstand high temperatures, automotive fluids and significant mechanical stress. This high-performance polymer serves as an ideal alternative to metals, as it is lighter weight, resistant to corrosive salts and fluids and offers optimal design capabilities.

Typical applications include:

Ryton® PPS provides exceptional value for electrical and electronic applications, as it exhibits excellent flow and low shrinkage for precision molding, superior stiffness and mechanical integrity for assembly and good stability for SMT soldering methods.

Typical applications include:

Ryton® PPS finds utility in a wide range of green hydrogen applications and components, due to its renowned thermal, mechanical, dimensional, and chemical stability. With exceptional lightweighting benefits and unique mechanical integrity, Ryton® PPS delivers ideal design flexibility for breakthrough innovations in the green hydrogen economy.

Typical applications include:

Ryton® PPS offers industrial OEMs a winning combination of properties, especially for injection molded applications and components. WIth outstanding thermal stability, broad chemical resistance and long-term strength, Ryton® PPS is well-suited to excel in various hostile environments and conditions.

Typical applications include:

|

PPS R-7-120BL BK RYTON |

PPS R-4-240NA NAT RYTON |

PPS V-1 NAT PWD RYTON |

|

PPS R-4-220BL BK RYTON |

PPS R-4-220NA NAT RYTON |

PPS R-4-230NA NAT RYTON |

|

PPS R-4-200BL BK RYTON |

PPS R-4 NAT RYTON |

PPS R-7-220BL BK RYTON |

|

PPS R-4-02XT BK RYTON |

PPS XK2340 BK RYTON |

PPS BR111 NAT RYTON |

|

PPS R-4-200NA NAT RYTON |

PPS XE3035NA NAT RYTON |

PPS R-4-230BL BK RYTON |

|

PPS BR42B NAT RYTON |

PPS XE5030BL BK RYTON |

PPS XE5500BL BK RYTON |

|

PPS R-7-120NA NAT RYTON |

|

|