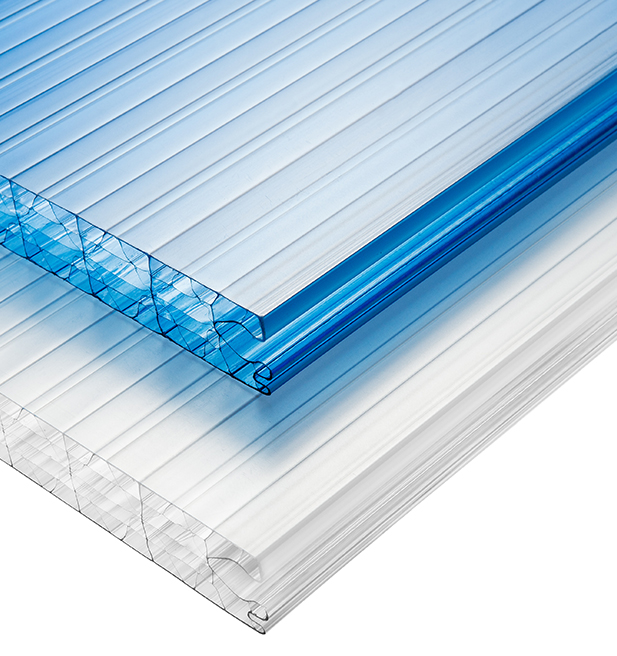

High Strength, Impact Resistance and Transparency

LEXAN™ is a polycarbonate thermoplastic resin produced by SABIC. It is known for its high strength, impact resistance, and transparency, which make it a popular choice for a wide range of applications. LEXAN is a versatile material that can be used in various end markets, including automotive, construction, and electronics, among others.

LEXAN™ is a versatile and durable material that is well-suited for a wide range of applications. It's high impact resistance and transparency make it an ideal choice for applications where durability and optical clarity are important. Additionally, its versatility allows it to be easily molded into complex shapes, making it a popular choice for designers and engineers across various industries.

LEXAN™ is a polycarbonate thermoplastic resin that is known for its excellent mechanical properties and optical clarity.

Characteristics and properties found across the product line include:

LEXAN™ offers several advantages for the aerospace industry. Its high strength-to-weight ratio makes it ideal for aircraft components where weight reduction is critical. LEXAN also provides excellent impact resistance and transparency, allowing for clear windows, canopies, and protective shields. Additionally, its ability to withstand extreme temperatures and its resistance to chemicals and flame spread make it suitable for various aerospace applications that require durability and safety compliance. Common applications include:

LEXAN™ offers several advantages for the mobility/automotive industry. Its high impact resistance and toughness make it suitable for exterior components that require protection against impacts and harsh weather conditions. LEXAN™ also provides excellent optical clarity and dimensional stability, making it ideal for automotive lighting applications. Additionally, its lightweight nature contributes to fuel efficiency and helps in reducing vehicle weight, thus enhancing overall performance. Common applications include:

LEXAN™ offers several advantages for the building and construction industry. Its high impact resistance and durability make it suitable for applications where safety and longevity are important, such as windows, skylights, and protective barriers. LEXANalso provides excellent transparency, allowing for natural light transmission while maintaining thermal insulation properties, contributing to energy efficiency in buildings. Additionally, its lightweight nature and design flexibility make it easy to install and customize for various architectural designs and construction projects. Common applications include:

LEXAN™ offers several advantages for the electrical and electronics industry. Its high dielectric strength and excellent electrical insulation properties make it suitable for applications such as electrical enclosures, connectors, and insulators. LEXANalso provides good dimensional stability and resistance to high temperatures, ensuring reliable performance in electronic devices and components. Additionally, its flame-retardant properties contribute to safety compliance in electrical and electronic applications.

Common applications include:

LEXAN™ offers several advantages for the healthcare industry. Its excellent chemical resistance and ease of sterilization make it suitable for medical equipment and devices that require frequent cleaning and disinfection. LEXAN™ also provides good impact resistance, transparency, and dimensional stability, making it suitable for applications such as protective shields, medical device housings, and equipment components. Additionally, its biocompatibility with ISO10993 or USP Class VI standards contributes to its suitability for healthcare applications.

Common applications include:

LEXAN™ offers several advantages for the packaging industry. Its high impact resistance and durability make it suitable for protecting fragile and sensitive products during transportation and handling. LEXAN™ also provides excellent transparency and clarity, allowing for product visibility and enhanced shelf appeal. Additionally, its dimensional stability and resistance to temperature variations make it suitable for packaging applications that require stability and integrity of the packaged contents.

Common applications include:

LEXAN™ offers several advantages for the signage and displays industry. Its excellent transparency and optical clarity make it suitable for creating vibrant and eye-catching signage and displays. LEXAN™ also provides high-impact resistance and durability, ensuring long-lasting performance in various indoor and outdoor environments. Additionally, its lightweight nature allows for easy installation and transportation of signage and displays. Common applications include: