Choose Your Language

Request a Quote

ALCOM® WP (Wear Protect)

- Home

- Supplier Products

- MOCOM

- ALCOM® WP (Wear Protect)

High-Performance Compounds for Enhanced Wear Resistance

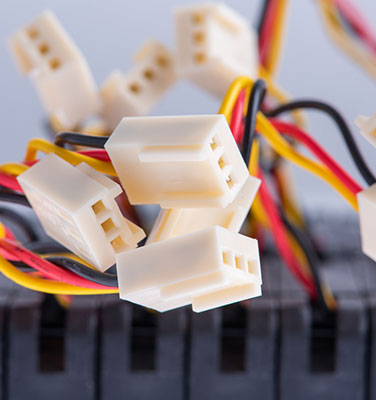

ALCOM® WP (Wear Protect) by MOCOM is a specialized line of thermoplastic compounds engineered to provide superior wear resistance and reduce friction in various applications. These materials are designed to extend the lifespan of components, minimize maintenance needs, and improve overall system efficiency.

ALCOM® WP compounds are formulated to address the challenges of wear and friction in demanding environments. By incorporating advanced fillers and reinforcing agents, these materials offer enhanced tribological properties, making them ideal for applications where durability and reliability are critical.

ALCOM® WP compounds are engineered with specific attributes to meet the rigorous demands of wear-intensive applications:

In the automotive sector, ALCOM® WP compounds contribute to the development of components that require high durability and low friction to enhance vehicle performance and longevity. These materials help reduce noise, wear, and energy loss in dynamic systems like powertrains and interiors. Typical applications include:

ALCOM® WP materials enhance the durability and functionality of consumer products that experience regular movement and friction during use. Their ability to reduce squeaking, sticking, and surface degradation contributes to a longer product life and better user experience. Typical applications include:

In electronic devices, these compounds are used to produce components that benefit from reduced friction and wear, ensuring consistent performance over time. Their excellent dimensional stability and surface finish also support miniaturization and precise part assembly. Typical applications industry:

For industrial machinery, these compounds are utilized to manufacture parts that endure high wear conditions, thereby reducing downtime and maintenance costs. Their resistance to abrasion and thermal stress makes them ideal for continuous operation in automated production environments. Typical applications include: