Best Part Mechanics. Highest Peak Temperature Performance. High Chemical Resistance.

ForTii® has unique PPA technology with high amide density. The ForTii platform includes polymers that are the highest crystalline, highest melting point and highest glass transition temperature among all PPAs.

ForTii® is a platform of high-performance, semi-aromatic polyamides (PPA) based on the unique “C4” diamine technology that enables best-in-class mechanical properties due to optimized crystallization morphology. ForTii® offers a unique balance of properties, including excellent dimensional stability, compatibility with lead free reflow soldering, and the highest stiffness and mechanical strength at extreme temperatures. The ForTii® platform offers material solutions in two product groups:

ForTii®

ForTii® is a PPA with high mechanical properties and good chemical resistance. The ForTii® grades have a melting temperature of 325°C (617°F) and a glass transition temperature of 125°C (257°F). Key Properties:

ForTii® Ace

ForTii® Ace is a high melting PPA with extreme mechanical properties and high chemical resistance. ForTii® Ace grades have a melting temperature in the range of 320°C (608°F) to 345°C (653°F) and a glass transition temperature ranging from 135°C (275°F) to 160°C (320°F). ForTii® Ace has the highest aromatic content (>50wt%) of all PPAs. Key Properties:

|

High temperature mechanics: The aromatic structure of ForTii combined with our unique C4 chemistry results in a polymer with a very high melting point of 325°C (617°F), complete with high stiffness across a wide temperature range. This in turn makes the heat distortion temperature for ForTii grades among the best in the industry. ForTii can replace metal at just 50% of the weight over a wide range of temperatures with no compromise on performance. Creep: Vs. Metal: Whether you intend to convert your current metal design into plastic to achieve weight reduction up to 50% or you want to reduce cost by eliminating compression limiters or threaded inserts, the excellent creep performance of ForTii Ace brings new metal replacement opportunities within reach. ForTii Ace gives optimal creep performance over a wide range of temperatures. Vs. PPA & PA66: Compared to PA66, Envalior's (formerly DSM Engineering Materials) PPA ForTii brings a significant advantage in terms of creep performance. ForTii outperforms low-Tg PPA materials (eg PA6T/66) and can match high Tg competitor PPAs (eg PA6T/6I). The increased performance of ForTii Ace provides additional creep performance at elevated temperatures up to 150°C or even in presence of moisture at lower temperatures. Vs. Thermoset materials: Thermoset materials are known for their good chemical resistance as well as their stability under creep loading. With ForTii Ace we provide engineers the possibility to rethink their thermoset designs into thermoplastic material solutions. Robust processing of ForTii Ace brings better yield rates within reach, providing direct economic benefits.

|

|

Chemical resistance: Where ForTii MX1 - MX3 brings on par chemical resistance to best-in-class PPA materials, Envalior’s ForTii Ace portfolio adds an additional step-up in chemical performance. For highest chemical stability, Envalior has developed a broad portfolio in ForTii Ace, which includes injection moldable grades in 30%, 40% and 50% glass fiber. Reflow soldering for surface mount technology: In the consumer market, there is a focus on producing smaller and lighter products with more functionality. The miniaturization of electromechanical components, like connectors and sensors, requires reflow soldering technologies since the contact pitch is so small. This causes a need for materials that can resist high temperatures up to 280°C (536°F). ForTii solves this challenge thanks to its combination of high melt temperature (325°C / 617°F) and low moisture absorption – which means that ForTii grades perform very well in SMT applications up to peak temperatures of 288°C (550.4°F). Deformation is minimal, and ForTii makes it far easier for designers to predict the warpage.

|

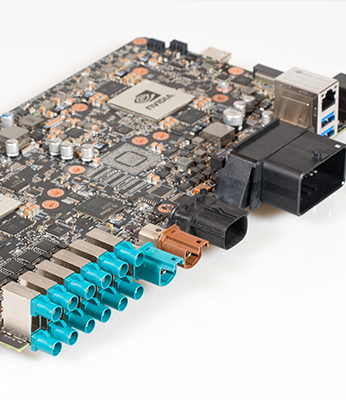

ForTii® provides superior mechanical and electrical performance with high mechanical strength. This material is high-temperature resistant with no blistering or electro corrosion. It has low warpage after soldering and high flowability which enables thin wall designs. ForTii has the highest safety and reliability for interconnects of ADAS sensors. Typical applications include:

ForTii® retains stiffness at high temperatures and is long-term heat resistant. ForTii is dishwasher proof and thermal shock resistant. This solution has a non-stick surface and is easy to clean. ForTii meets food contact regulations including EU 2011-10 and FDA. Typical applications include:

Because of its excellent compatibility with lead free surface mount technology - along with good dimensional stability and high mechanical properties - this halogen-free, flame-retardant material is viable for supporting key industry trends in convergence and aesthetics. Its electrical properties offer the highest CTI level possible, which when coupled with dimension stability, make ForTii extremely well suited to highly demanding applications in the electronics and electrical industry. Typical applications include:

|

PPA F11 BLK BK FORTII |

|

PPA GF35 MX15HR BLK BK00001 FORTI |

|

PPA ACE WX53-FC BK00001 FORTII |