Providing a Broad Portfolio with Global Grades with Global Specifications

Envalior's (formerly DSM Engineering Materials) Akulon® portfolio covers virtually all possible applications with grades suited to all processing techniques, including extrusion, injection, and blow molding.

From superior impact strength and high heat resistance to excellent flame retardancy, Akulon® delivers properties that help you produce greener, lighter, and smarter products.

Envalior’s standard offering consists of:

The Akulon® portfolio covers virtually all possible applications with grades suited to all processing techniques, including extrusion, injection, and blow molding. Akulon polyamide 6 & 66 resins represent the best value in all-purpose engineering materials. For molded parts, they offer an excellent balance of easy design and processing with outstanding mechanical properties over a wide temperature range and in diverse operating environments.

Thermal:

Akulon® is ideal for injection molding thanks to its unique combination of short- and long-term low and high temperature properties under various chemical conditions. Akulon® has a continuous-use temperature of up to 365°F (185°C). In fact, polyamide 6 delivers better long-term performance at high temperatures than polyamide 66 and should be the preferred material for any application running for extended periods above 301° F (150°C).

Mechanical:

Akulon® has a full portfolio that provides excellent long- and short-term mechanical properties. For high mechanical strength, Akulon® has 50% and 60% glass filled grades in the portfolio. These are suitable for metal replacement where high strength and fatigue are key.

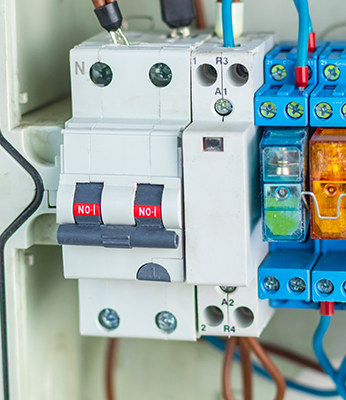

Electrical:

Akulon® has excellent electrical properties and conforms to all global standards.

Flame retardant:

The Akulon® product line provides a full range of flame-retardant grades. The Akulon® portfolio contains unfilled grades, as well as glass or mineral filled grades, including a halogen free flame-retardant portfolio.

Akulon® is a thermoplastic with high-heat resistance and high-speed tensile properties. This material is stiff and tough, making it compatible for applications with expansion rubber or foam is applied to molded parts. It can yield faster molding than standard PA6, which makes it ideal for applications requiring thinner wall designs. Typical applications include:

Akulon® is a lighter weight material compared to metals, which makes it easier to use for integration and assembly. Additionally, it has a better welding strength and surface appearance than PA66. With its ability to perform across a wide temperature range and in diverse conditions, Akulon is a reliable solution for power tool housings, outdoor power equipment and outdoor sports gear. Typical applications include:

Akulon® is a reliable solution for electrical applications with excellent short-circuit properties, including residual dielectric strength and thermo-mechanical endurance. This material is impact resistance, performs at low & high temperatures, and offers excellent CTI and arc resistance values (UL94 V2 at 0.75 mm certification). Most grades are available with halogen-free flame retardancy. Typical applications include:

|

PA6 K222-D NA99001 AKULON |

PA6 FL-P NA99001 NAT AKULON |

PA6 K122/F NA99001 AKULON |

|

PA6 K224-PG8 BK25018 AKULON |

PA6 K224PG6 999999 NAT AKULON |

PA6 K223TP4 999999 NAT AKULON |

|

PA6 K224-HG6U BK223 BK AKULON |

PA6 K224-G3 NA99001 AKULON |

PA6 K224-HG0 BK25018 AKULON |

|

PA6 K224-PG6 BK25018 AKULON |

PA6 K-FHG6/A BK00001 AKULON |

PA6 K224-LPG6U OR52705 AKULON |

|

PA6 K224-KGM35 BK9719 AKULON |

PA6 K224-HG6 BK00001 AKULON |

PA6 KFHG0 T30306 BK AKULON |

|

PA6 K224-LG6U BK9855 AKULON |

PA66 M-1016 BK6793 AKULON |

PA6 K-FKG8 BK00001 AKULON |

|

PA6 FL-LP BK26021 AKULON |

PA6 K222-KGV4 S20620 GY AKULON |

PA6 FL40-HPX1 BK00002 AKULON |

|

PA6 K224-G6U NA99001 AKULON |

PA6 K223-TP4 BK00001 AKULON |

NY J 17/30/VO NT AKULON |

|

PA6 K224-LPG6U GY35007 AKULON |

PA6 K-FKG3 BK00001 AKULON |

PA6 K224PG8 999999 NAT AKULON |

|

PA6 K224-HG3 BK00001 AKULON |

PA6 K224-HG6U NA99001 AKULON |

PA6 K222-KGV4 BK29002 AKULON |