Lower Moisture Uptake than PA66 with a Higher Mechanical Performance and Excellent Surface Finish

EcoPaXX® is a high-performance aliphatic, biobased polyamide that uniquely balances the benefits of typical short and long chain polyamides, such as low moisture uptake and high mechanical performance. EcoPaXX has wide applicability and is especially popular as a PA66 performance booster since it can be processed in the same tools.

EcoPaXX® is Envalior's (formerly DSM Engineering Matieral) most established biobased engineering plastic. It combines Envalior's propriety C4 technology with the power of nature’s C10 building block derived from castor plants, which do not compete with the food chain.

The combination of the short C4 block and the long C10 block gives EcoPaXX® high mechanical properties of typical short chain polyamides but combines these with lower moisture update and higher chemical resistance more typical of long chain polyamides. EcoPaXX® can easily be processed in PA66 tools while resulting in better surface quality. This makes it an ideal candidate for when performance, aesthetics and sustainability come together.

|

Moisture uptake: EcoPaXX's® combination of short C4 chain and long C10 chain results in a unique balance of high crystallinity/stiffness combined with low moisture uptake and high chemical resistance. Specifically, EcoPaXX® PA410 has 30% lower moisture uptake than PA66 while exhibiting similar glass transition (70°C / 158°F) and melt temperature (250°C / 482°F). As a result, EcoPaXX® has the highest conditioned modulus (1,7GPa) among aliphatic polyamides. Hydrolysis resistance: EcoPaXX® has specialized food contact and drinking water grades, which are approved by all major institutions (e.g., KTW, W270, NSF61, WRAS, ACS, EU 11/2011, FDA). EcoPaXX is approved for both warm and hot water applications. Due to its low moisture uptake and high mechanical strength, EcoPaXX® shows excellent hydrolysis resistance with no water leakage in lifetime cycle tests up to 1 million cycles. EcoPaXX® drinking water grades have higher Tg of approximately 85°C (185°F) and show superior long-term hydrolysis resistance in hot water aging (110°C / 230°F) compared to low Tg PPA. Low carbon footprint: EcoPaXX® carbon footprint is assessed cradle-to-gate, using Envalior‘s in-house lifecycle assessment experts. EcoPaXX® has the lowest carbon footprint amongst common polyamides, including biobased polyamides. The Carbon footprint can be lowered further if biomass balancing is used for the C4 monomer. This is an option available for certain grades upon customer request. Mass balancing does not change material properties and is externally certified through ISCC.vOur team can assist with calculations for specific EcoPaXX® grades, and we also work with our customers on cradle-to-grave assessments for specific end applications. |

|

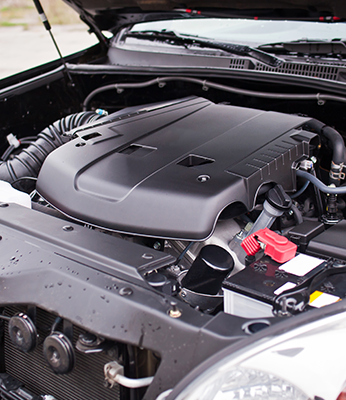

High dielectric strength: EcoPaXX® has several grades that are engineered to meet V2 and V0 flammability and high glow-wire temperatures. All EcoPaXX® grades are halogen-free and hence do not release associated toxic compounds upon burning. EcoPaXX has similar dielectric strength as PA66 in the dry state, but significantly higher dielectric strength after conditioning. This makes EcoPaXX® more insulating, resulting in higher safety for electrical applications. It also means insulating parts with EcoPaXX® can be designed thinner than with PA66 without sacrificing product safety. Processing: EcoPaXX® can be processed very similarly to PA66. It has a very wide processing window (270-310°C / 518-590°F) and high melt stability. Its faster crystallization rate vs. PA66 results up to 20% lower cycle times. At the same time, EcoPaXX® has excellent surface finish even with 30%GF content, making it suitable for decorative applications, such as engine covers. Salt resistance: EcoPaXX® is extremely resistant to CaCl2 salt with no mechanical failure even after 2,500 hours being submerged in the solution, especially when compared to approximately 5 hours for PA66. Water/glycol aging: EcoPaXX® has approximately 20% higher retention of tensile properties compared to PA66 grade. This results in a five-fold increase in weld line performance (tested on tensile bars), as well as a three-fold increase in product lifetime (tested on automotive expansion tank, design dependent). Therefore, it is possible to design parts with lower thickness and hence weight compared to PA66 while maintaining similar or higher performance. |

EcoPaXX® is an excellent solution for applications requiring under-the-hood temperatures of 105 to 150°C (221 to 302°F), internal coolant temperatures, the ability to withstand exposure to water/glycol and good welding properties. EcoPaXX offers superior chemical and dimensional stability and weld-line strength after aging. Typical applications include:

EcoPaXX® PA410 is a lightweight, sustainable choice compared to traditional aluminum window profiles. It is a reliable solution due to its high melting point of 250°C (482°F), making the material suitable for the powder-coating process. Manufacturers can increase the energy efficiency of buildings — important not only for users but for environmental product declarations. Typical applications include:

EcoPaXX® is a lead-free solution, making it ideal for water and food contact applications. This biobased polymer has high strength (static pressure > 500psi, bending strength >61Nm) and showed no evidence of water leakage during a 1 million cycle test. EcoPaXX property qualities include high crew thread strength, superior stiffness and toughness, good hydrolysis resistance, and high dimensional stability. Additionally, EcoPaXX (PA410) is a reliable, sustainable choice for abrasive monofilaments because of its wear and friction properties. Moreover, it is a reliable, sustainable choice for mountaineering shoes due its low-temperature resistance. Typical applications include:

|

|

|

PA410 Q-E7300 BK00002 ECOPAXX |

|

PA410 Q-HG10 BK127-4002 ECOPAXX |

|

PA410 Q170E-H NAT ECOPAXX |

|

PA410 Q210E-H BK00001 ECOPAXX |

|

PA410 Q210E-HU NA99001 ECOPAXX |

|

PA410 Q170-E NAT ECOPAXX |