Choose Your Language

Request a Quote

Ultramid®

- Home

- Supplier Products

- BASF

- Ultramid®

BASF’s Ultramid® engineering plastics portfolio includes dozens of grades of polyamide molding compounds on the basis of PA6, PA66, PA610 and various co-polyamides including PA66/6. The range also includes the specialized Ultramid® Advanced portfolio of high-performance, semi-aromatic polyphthalamides such as PA6T/6, PA6T/66, PA6T/6I and PA9T.

Learn More About Ultramid® Advanced

Ultramid® polyamides are known for their high mechanical strength, stiffness and thermal stability. In addition, Ultramid® offers good firmness at low temperatures, favorable sliding friction behavior and easy processability. Ultramid® molding compounds are available unreinforced, reinforced with glass fibers or minerals, and reinforced with long-glass fibers for special applications.

Ultramid® polyamide (PA) can be used for many applications because of its versatile and customizable characteristics. Applications include automotive and mobility, electrical and electronics (E&E), construction, furniture, sanitary ware and more. In addition, Ultramid® can be processed by a variety of methods including extrusion and injection molding. Characteristics and properties found across Ultramid® product lines include:

Ultramid® grades for appliances can offer flame retardant and electronic qualities. Their high toughness, good mechanical performance and chemical resistance are ideal in this market. In addition, polyamides can be transparent or translucent and can have glossy or scratch-resistant properties. Typical applications include:

For decades, BASF has been a globally-recognized leader in the development of challenging components and materials for the automotive industry. Ultramid® engineering plastics provide excellent dimensional stability and wear resistance, even when exposed to high temperatures, UV, and harsh weather conditions. Typical applications include:

Ultramid® polyamides are fantastic engineering plastics ideal for improving strength while being lighter than steel. The Ultramid® portfolio includes grades that fulfill technical specifications and health and safety requirements for sanitary and water applications. Common applications include:

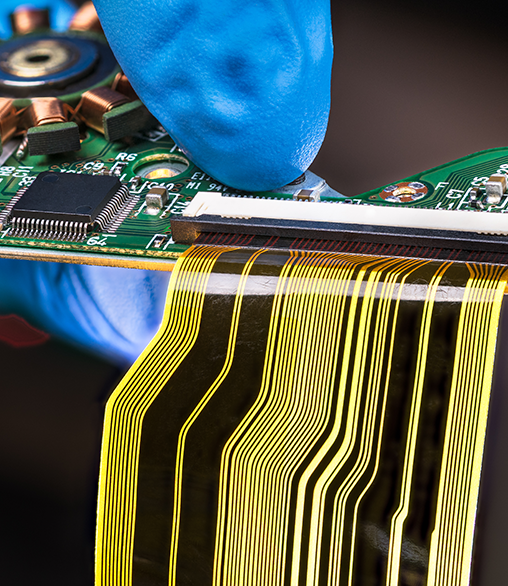

When it comes to thermoplastics in electrical and electronics markets, there is increasing demand for smaller components that are flame retardant and deliver improved performance. Ultramid® grades possess excellent electrical properties, mechanical characteristics, and heat resistance. Typical applications include:

High mechanical resilience combined with good toughness makes Ultramid® an excellent choice for many applications in the furniture industry, where traditional materials such as metal or wood can be replaced by plastics with tailor-made properties. Typical applications include:

Power Tools must be durable, efficient, and have excellent performance. Material selection plays a significant role in determining if a power tool can stand the test of time. Ultramid® polyamides provide high stiffness, excellent impact strength, flame retardance and very good media resistance. Ultramid® plastics make excellent replacements for select metal parts, making tools lighter and easier to use. Typical applications include:

|

PA6 8202 NAT ULTRAMID |

||

|

PA6 8202 WT6407 ULTRAMID |

PA6 8267GHS BK106 ULTRAMID |

|

|

PA6 8267GHS NAT ULTRAMID |

PA6 B3GM35 Q649 BK23220 ULTRAMID |

|

|

PA6 8202CHS GY7470 ULTRAMID |

PA6 8333GHIHS BK102 ULTRAMID |

PA6 B3M8 NAT ULTRAMID |

|

PA6 8202HS BK102 ULTRAMID |

||

|

PA6 8202L NAT ULTRAMID |

PA6 B3WGM24 BK30564 ULTRAMID |

|

|

PA6 8233G NAT ULTRAMID |

PA66 1503 2 ND3007 BK ULTRAMID |

|

|

PA6 8233GHS BK102 ULTRAMID |

||

|

PA6 8233GHS BK106 ULTRAMID |

||

|

PA6 8233GHS NAT ULTRAMID |

PA6 B3G7R01 RD7920 ULTRAMID |

|

|

PA6 B3GM35 EBONY23227 ULTRAMID |