Choose Your Language

Request a Quote

Ultramid® Advanced

- Home

- Supplier Products

- BASF

- Ultramid® Advanced

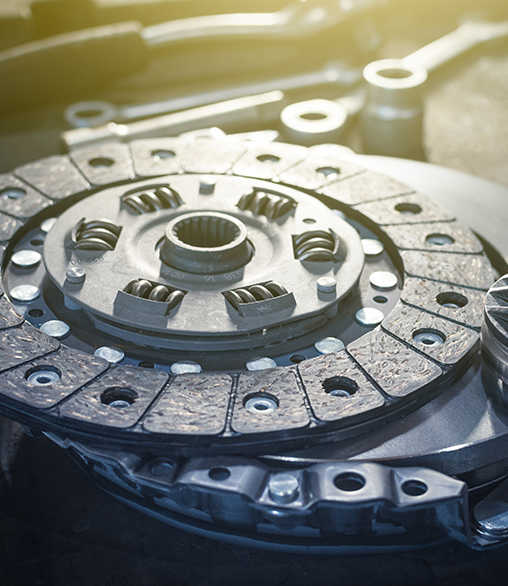

From the automotive and the E&E industries to mechanical engineering and consumer goods, Ultramid® Advanced polymers are engineered for high-performance applications. the new Ultramid® Advanced Polyphthalamide (PPA) portfolio by BASF consists of five polymers with about 50 compounds. Widely used as a choice for metal replacement, Ultramid® Advanced polymers are ideal for lightweighting, allowing greater design options at a lower cost compared to parts made from metal.

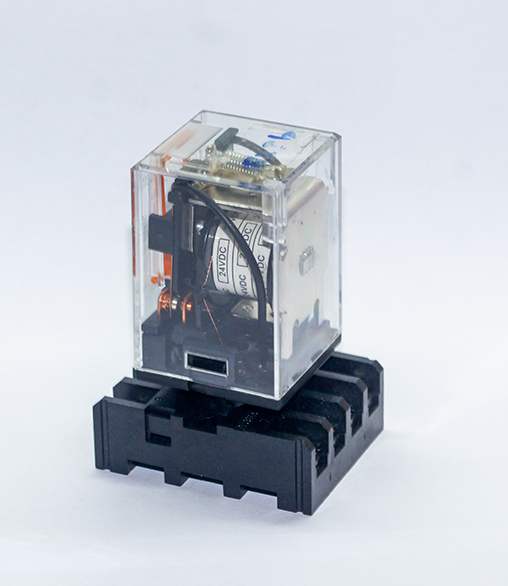

Ultramid® Advanced molding compounds are available unreinforced or reinforced with minerals, short or long glass fibers, or carbon fiber for special applications. These polyphthalamides are known for their high mechanical strength, stiffness and thermal stability. In addition, Ultramid® Advanced offers good firmness at low temperatures, exhibits favorable sliding friction behavior, and is highly processable These PPA polymers are made to withstand high temperatures while maintaining their strength, including lead-free soldering processes across a variety of industries.

Ultramid® Advanced PPA materials can be used for many applications because of their customizability and high-performance mechanical and thermal properties. Applications include automotive and mobility, electrical and electronics, construction, furniture, sanitary ware and more. In addition, Ultramid® Advanced can be processed by a variety of methods including extrusion and injection molding.

The Ultramid® Advanced portfolio includes grades with the following options:

Characteristics and properties found across all Ultramid® product lines include:

The polyamide 9T (PA9T) Ultramid® Advanced N shows constant mechanics up to 100°C (glass transition temperature: 125°C), outstanding chemical resistance, low water absorption and excellent tribological properties. Typical applications include:

T1000 polyamide 6T/6I (PA6T/6I) is the product group with the highest strength and stiffness in the Ultramid® Advanced family. T1000 polythalamides exhibit stable mechanical properties at temperatures of up to 125°C (dry) and 80°C (conditioned). They offer high resistance to humidity and to aggressive media – outperforming conventional polyamides and many other PPA materials on the market. Typical applications include:

Ultramid® Advanced T2000 is the ideal solution for parts that require high, constant stiffness and strength over a broad temperature range, resistance to heat and humidity, and optional flame-retardant (FR) properties. Common applications include:

Ultramid® T KR was among the first PPAs on the market. This polyamide 6T/6 (PA6T/6) has a high melting point of 295°C and while remaining easy to process. It provides high stiffness and strength, especially in the presence of humidity or high temperatures, and at the same time exhibits the highest toughness of any PPA material. Ultramid® T KR possesses excellent heat resistance: The relative tracking index (RTI) of 160°C at 0.4 mm of Ultramid® T KR4340 G6 is one of the highest RTIs in the polyamide market. Typical applications include:

Ultramid® One J is a high-temperature polyamide that outperforms PA66 in terms of mechanical and dielectric properties, especially in the presence of humidity and elevated temperatures. This polyamide 66/6T (PA66/6T) shows high flowability and easy processing similar to PA66, and its excellent mechanical properties are unaffected by mold temperatures. Ultramid® One J opens up new, colorful possibilities with white color shades for miniaturization parts with electrical protection. The UL cards testify to excellent RTI and GWIT values, and the flame retardant used is halogen-free. Typical applications include: