Choose Your Language

Request a Quote

AuroraGuard™

- Home

- Supplier Products

- Aurora Material Solutions

- AuroraGuard™

Advanced Flame-Retardant Polymer Compounds

AuroraGuard™ is a premium line of high-performance polymer compounds developed by Aurora Material Solutions, designed to meet the stringent requirements of industries where high heat, flame retardancy, low smoke emission, or zero-halogen content are critical. The AuroraGuard portfolio includes various materials such as PC alloys, high-heat RPVC, flexible PVC (FPVC), TPEs, and more—each formulated to deliver enhanced safety, durability, and regulatory compliance across demanding applications.

.jpg)

AuroraGuard™ compounds are engineered to meet the rigorous demands of various industries. By incorporating AuroraGuard™ materials, companies can achieve:

AuroraGuard™ compounds are designed to meet diverse application requirements, offering:

.jpg)

AuroraGuard™ compounds meet stringent FST (flame, smoke, toxicity) standards while maintaining lightweight, durable performance. They're an ideal choice for interior cabin parts and technical components that require consistent behavior in high-stress environments. Typical applications include:

.jpg)

Designed for environments that demand durability and code-compliant flame retardancy, AuroraGuard™ compounds—especially CPVC and FR PVC—offer low smoke emission, UV stability, and impact resistance. Ideal for both structural and electrical components in residential and commercial buildings. Typical applications include:

.jpg)

With excellent flame and smoke performance, AuroraGuard™ is ideal for protective housings, connectors, and enclosures. These materials combine electrical insulation, thermal resistance, and compliance with industry fire safety standards, helping reduce risk in consumer and industrial electronics. Typical applications include:

.jpg)

AuroraGuard™ compounds provide high heat resistance, flame retardancy, and dimensional stability, making them well-suited for both interior and under-the-hood parts. Their low-smoke, zero-halogen formulations help meet vehicle safety standards across combustion and electric platforms. Typical applications industry:

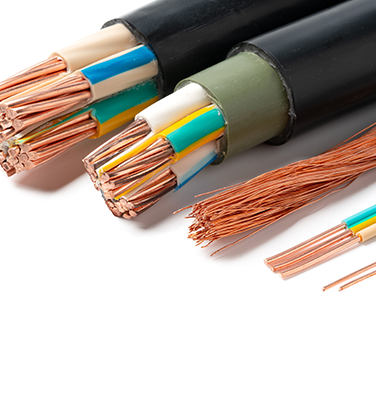

AuroraGuard™ compounds deliver low smoke, zero halogen (LSZH) performance, making them ideal for safe, high-performance cable jacketing and insulation. They offer thermal stability, flame resistance, and flexibility, ensuring compliance with fire codes and long-term reliability in power, control, and data cable applications. Typical applications include: