Ask an Expert

Application Development

- Home

- Services

- Technical Solutions

- Application Development

Application development involves identifying and defining what is needed from a specific part or system. There are several variables that determine the success of that process, such as:

By considering these variables, product development teams can differentiate essential from nice-to-have and define the product requirements. The part design and material selection process can then be evaluated to ensure that the product requirements are met.

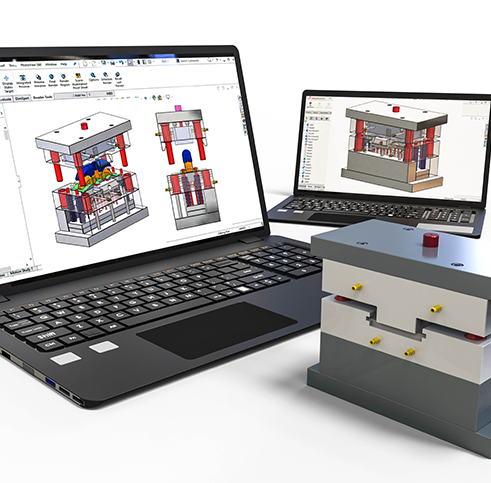

Part design in the plastics industry generally requires identifying the packaging space, aesthetic, regulatory, and performance criteria of the part and assembly. Part design is critical for manufacturability, as well as for achieving quality and cost targets. The material properties should support the design requirements and can help product development teams identify potential risks that need to be vetted early in the development process. Tooling must be designed and constructed to meet the needs of the part design to ensure that the associated timing, costs, and longevity of the part itself will meet the needs of the application. Nexeo Plastics’ Application Development Engineers (ADE) look at the big picture, understand the requirements, and collaborate with our customers to help them reduce risk and develop optimal parts at a competitive cost.

You may reach out to our application development engineering team during any step of your product development cycle, from concept to manufacturing and each step in between. Engaging our ADE’s early in the process can help ensure the best possible outcome for your application.

We can assist with topics such as plastic part design, material specification, tool design, failure analysis, and manufacturing improvement. In addition, our ADE’s can provide material selection support based on a number of criteria such as:

Our ADE team can provide an unbiased third-party technical perspective and can serve as a second set of eyes by helping you review your product, material, and manufacturing process. We provide engineering resources to help our customers be successful. Our mission is to support and collaborate with your engineering and manufacturing teams to assure a successful launch. We also assist our customers with inquiries on several topics, including part design, material selection, and manufacturing best practices.

We go beyond traditional distribution of thermoplastic resins to support our customers with the technical expertise they need to help them be successful both on the front-end of product development, as well as on the back end, by assisting with troubleshooting and manufacturing issues. Our ADE team’s expertise can help you mitigate risks and may ultimately save you time and money in the long run.