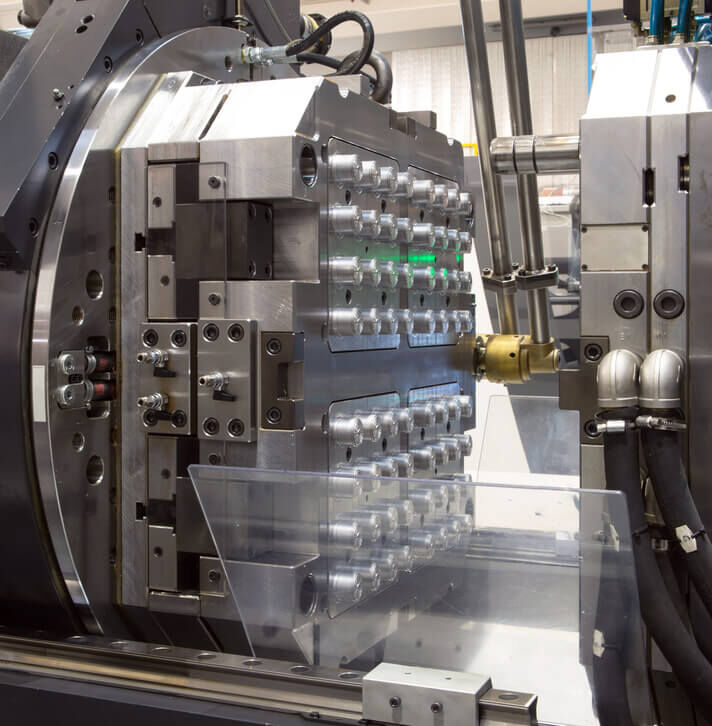

From commodity to engineered thermoplastic resins, we can help you in your specialized and high-volume mobility/automotive, electronic, healthcare, packaging, construction, toys and household applications. Our team of experts work with you wherever you are in your production process to help you meet application requirements including regulatory, sustainability, and performance standards.

Read our blog: Troubleshooting Tips for Plastic Injection Molding

Understanding the Requirements for Injection Molding Materials

We work closely with you and our suppliers to help you meet physical property requirements:

Beyond Logistics

Delivering thermoplastics when and where you need them is what we do. Helping you overcome material challenges is our passion. Whether it is material specification, part design, process optimization, troubleshooting or assistance with manufacturing tests, we can help you tackle your injection molding challenges. Our team works to understand your overall business objectives including the fit, form, and function of your part, as well as uncover ways to achieve efficiencies in your production process, supply chain and overall costs. With more than 8500 thermoplastic resins and compounds to choose from, we work with you every step of the way to find the ideal material to help you achieve your business objectives.