Choose Your Language

Request a Quote

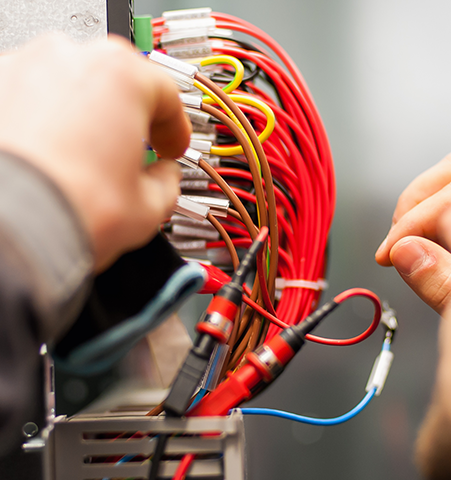

Wire & Cable Compounds Thermoplastic Solutions

- Home

- Industries

- Wire & Cable

Our material solutions can help deliver performance and industry standards for various wire and cable applications including underground and underwater cables, electronic cables, industrial cables, mobility/automotive, construction wires, and much more.

We work closely with our suppliers to help ensure materials adhere to applicable safety, testing and performance-based standards, including:

Our thermoplastics and compounding materials include low-smoke zero halogen (LSZH) compounds, plenum and riser compounds, specialty compounds and color concentrates, which deliver flame and chemical resistance, excellent chemical strength, insulation protection, color compounding and much more.

Plastic compounds are used in wire and cable applications to provide insulation, jacketing, and protection. These materials help ensure electrical performance, mechanical durability, chemical resistance, and safety. Thermoplastic compounds also offer flexibility, flame retardancy, and resistance to heat, moisture, and abrasion.

Thermoplastic compounds are commonly used in applications such as:

Wire and cable compounds are engineered to meet specific performance requirements and often include features such as:

PVC compounds are widely used in the cable industry for their versatility and cost-effectiveness. Benefits include:

Our rubber, polyolefin, chlorinated polyethylene (CPE) compounds and polyvinyl chloride (PVC) resins are designed to be flexible, chemical, weather and ozone resistant; withstand low temperatures and have excellent physical and mechanical properties.

In the automotive and mobility industry, wire and cables must perform under extreme environmental and mechanical stress. Common plastic compounds used include:

Read more about our automotive and mobility thermoplastic solutions.

Our extrusion grade nylons (PA 6) for wire and cable jacketing are designed to meet requirements for thermoplastic high-heat-resistant, nylon-coated wire (THHN). Additionally, thermoplastic and water-resistant nylon-coated (THWN) wires and thermoplastic flexible fixture nylon wires (TFFN) are used in constructions and other applications, where toughness and abrasion resistance are important

Industrial applications, including wind turbine and robotic cables, can benefit from our thermoplastic elastomers (TPEs) that provide flexibility, low temperature and oil resistance.

In industrial environments, wire and cable plastics are used for power transmission, control systems, automation equipment, and instrumentation. The materials must withstand harsh conditions, including exposure to oil, UV, moisture, extreme temperatures, and physical stress. Common plastics used include:

Flame retardancy, abrasion and impact resistance, flexibility, resistance to oils, solvents, and industrial chemicals are features of thermoplastics used in industrial wire and cable applications.

Our polybutylene terephthalate (PBT) materials are ideal for electronic, electrical, communications and fiber optics, where low warpage, good chemical resistance, excellent mechanical strength and low water absorption rates are key. Additionally, polyolefin compounds are ideal for insulation and jacketing applications.

For the electrical and electronics industry, cable compounds must ensure signal integrity, electrical insulation, and flame resistance. Common plastics used include: