Extreme Chemical Resistance, Dimensional Stability and Flame Retadant.

Xytron™ is a high-performance plastics compound based on linear polyphenylene sulfide that contributes to three key strengths:

Xytron™ offers extreme chemical resistance, dimensional stability, and is intrinsically flame retardant. It also offers high stiffness up to a glass transition temperature of 90°C, with a continuous use temperature between 240-260°C. (464-500°F). Xytron™ is well suited for a broad range of automotive, electrical and electronics, and specialized industrial applications.

|

Hydrolysis resistance: It is known that PPS and glass are both good at hydrolysis resistance. But the interface of glass and PPS is the weak point for a glass reinforced PPS compound during the hydrolysis process. Thanks to good bonding technology, Xytron™ G4080HR outperforms competitors’ materials. The retention strength is still around 80% of its initial value after 3,000 hours of aging at 135°C (275°F). Long-term heat aging performance: Due to its highly stable chemical bonds, Xytron™ G4010T shows extremely good heat aging performance. Even after aging at 230°C (446°F) for 6,000 hours, Xytron™ G4010T still shows > 60% tensile strength retention. High purity: With Xytron™ linear PPS, there is very limited leaching due to high purity levels. It can also be widely used in water management and hydrogen fuel cells. |

|

Dimension stability: Xytron™ G4020DW-FC shows almost ZERO moisture absorption. Even if the specimen of G4020DW-FC is soaked in 85°C (185°F) water for 72 hours, the absorbed water is only 0.2%, which results in a dimension increase by approximately 0.03% in flow direction and 0.05% in transverse direction. Creep resistance at an elevated temperature: Xytron™ shows very good creep performance even at elevated temperatures. Thermal conductivity: By using different types of additives, good electrical properties and dimension stability, plus long-term high temperature resistance and hydrolysis resistance performance, can be combined in thermal conductive materials. |

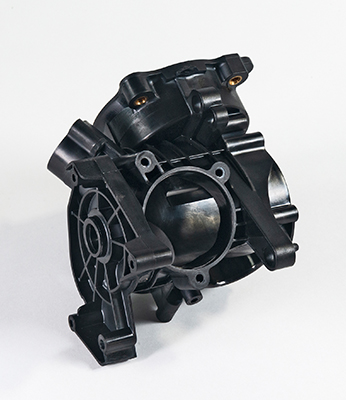

Xytron™ delivers outstanding performance in water/glycol, making it suitable for long-term contact with water/glycol. It provides an excellent surface finish that is rigid and dimensionally stable. Additionally, it offers a high weld line strength. As this material is easy to mold and is high impact resistance, production costs can typically be reduced due to shorter cycle times. Furthermore, Xytron™ offers best in class shielding carbon fibre (CF) composites with the highest shielding levels, thermal conductivity and good mechanics. Composites reduce wall thicknesses by 4x and increase the conductivity to metal levels. Typical applications include:

Engine heaters heat engine coolant to allow for easy engine start-up, regardless of ambient temperatures. The engine block heater is required to operate in continuous contact with coolant at temperatures between 35-50°C (95-122°F). Xytron™ offers long-term high temperature and hydrolysis resistance and allows for easy processing.

Xytron™ is free from potentially harmful leachable substances and complies with drinking water act regulations observed worldwide, making it ideal for the manufacturing of eco-friendly, lead-free water heater and boiler parts. Xytron™ generates lower flash, which improves production yield, reduces the length of post-production processes, and offers greater design flexibility. Typical applications include: